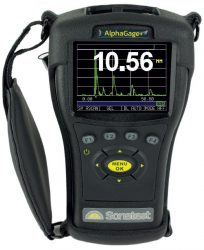

AlphaGage+

AlphaGage+ is a very versatile piece of equipment as it can be used to perform integrity assessments of metal steel works affected by corrosion or erosion processes as well as to measure precisely the thickness of a critical piece of equipment.

AlphaGage+ P – Precision Gauge

Precision gauges are particularly effective when using single element transducers and delay line wedges in Pulse-Echo configuration to achieve higher accuracy than corrosion gauges and meet very strict quality control requirements.

Standard features include: a wide thickness range (up to 20” in steel), a 1 micron resolution (0.0001” or 0.001

mm), store and recall up to 2,700 setups, a high end 30 MHz bandwidth instrument and a “Zoom Auto Tracking” functionality.

Typical Applications

- Castings & turbine blades

- Plastic parts

- Coil steel & auto body panels

- Fiberglass & gel coatings

- Velocity Measurement

- Aluminium, glass, ceramics & zinc

AlphaGage+ C – Corrosion Gauge

Without being limited to, the corrosion gauges generally use dual element transducers in a Pitch & Catch

configuration to reduce surface problems and measure accurately the remaining wall thickness of metal

structures subject to corrosion.

Standard features include: a wide thickness range (up to 23” in steel), coating thickness and substrate thickness displayed simultaneously on gauge with live waveform, temperature correction and file compare features for data logger versions.

Typical Applications

- Pipes & Boiler tubes

- Pressure vessels

- High temperature applications

- Storage tanks

- Ship hulls

- Steel beams

Specifications

| Transducers | Single or Dual element (according to gauge model) |

| Thickness Range (fct. of probe & material) | Typical range in steel (corrosion mode): 0.508mm to 584mm

Typical range in steel (precision mode): 0.152 to 584mm and as low as 0.076 mm in plastics. |

| Velocity Range | 0.508 to 18.699 mm/s |

| Resolution | On corrosion mode: 0.01 mm or 0.1 mm

On precision mode: 0.001 mm or 0.01 mm |

| Measurement Rate | 4 Hz or 25 Hz |

| Bandwidth | 0.5 MHz to 30 Mhz (-3dB) |

| Differential Mode | Displays the difference from actual thickness measurement in absolute or percentage of a user entered reference value. |

| Fast Min/Max | Displays minimum and maximum simultaneously with actual thickness at up to 25 Hz. |

| Gain Settings | Manual adjustment (Low, Standard, High) and Automated Gain Control (AGC) |

| Alarms | According to alarm conditions, the gauge can vibrate (ideal for loud environments), beep or change the colour of the main display. |

| Connector Type | Lemo 00 |

| Size | Length 184 mm x Width 102 mm x Height 51 mm |

| Weight | 520 g with internal Li-ion battery 450 g with optional alkaline tray (3xAA batteries) |

| Display | 3.5” high resolution colour TFT display, 320 x 240 pixels, sunlight readable, including multiple colour pallets. |

| Operating Temperature | -20 to 50°C (-4 to 122°F) |

| Operating Time | 27h @ 4 Hz & 11h @ 25Hz in continuous operation with standard 3.7V Li-ion internally rechargeable battery (optional alkaline tray 3xAA batteries available for extended life) |

| Setup Storage | Internal memory for up to 2,700 calibration and preset setup fiel s. |

| Data Storage | With Data Logging (DL) option, a 2GB micro SD card is included (expandable up to 32GB) |

| Certifications | CE certified, RHOS complaint and designed for IP67. |

| Warranty Limited | 2 year warranty under normal use on parts and labor. |